|

Pan-Pioneer

promote our variety of stranding

devices for different applications. During this slight-profit years,

We devote a lot of efforts on design and manufacturering for

cost-down without sacrificing anything. For each stranding machine models

we have different options for different applications. We also offer

custom-design service for special need from Buyers. This is based on

our knowledge to cable manufacturing and well-experienced design

team group who can satisfy customers with design of

creativity. Pan-Pioneer

promote our variety of stranding

devices for different applications. During this slight-profit years,

We devote a lot of efforts on design and manufacturering for

cost-down without sacrificing anything. For each stranding machine models

we have different options for different applications. We also offer

custom-design service for special need from Buyers. This is based on

our knowledge to cable manufacturing and well-experienced design

team group who can satisfy customers with design of

creativity.

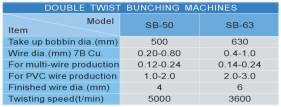

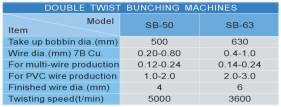

Starting from

500mm ,560mm and 630mm high speed bunching machine

, 800mm 1000mm 1250mm and 1600mm double

twisting machines, with variety of devices and

accessories,

Pan-Pioneer provide complete line-up Bunching / Double

Twisting Machines for customer satisfactory. All these Bunching /

Double Twisting machines are designed for with a user-friendly

oriented operation, such as Hydraulic

Front loading / Loading (which means no cranes needed )

lifter , TFT screen monitor for information display Starting from

500mm ,560mm and 630mm high speed bunching machine

, 800mm 1000mm 1250mm and 1600mm double

twisting machines, with variety of devices and

accessories,

Pan-Pioneer provide complete line-up Bunching / Double

Twisting Machines for customer satisfactory. All these Bunching /

Double Twisting machines are designed for with a user-friendly

oriented operation, such as Hydraulic

Front loading / Loading (which means no cranes needed )

lifter , TFT screen monitor for information display

The pitch range of each machines are

custom-designated available. These pitches are set by changing the

transmission gears which are easily replaced by just a simple

wrench. By selecting the different gear ratio , operators can setup

the pitches of the products they need. The purpose of the design

this way instead of setting on the touch-screen-monitor with two

independent motors (this model is an option) is because : The pitch range of each machines are

custom-designated available. These pitches are set by changing the

transmission gears which are easily replaced by just a simple

wrench. By selecting the different gear ratio , operators can setup

the pitches of the products they need. The purpose of the design

this way instead of setting on the touch-screen-monitor with two

independent motors (this model is an option) is because :

First of all, most of time , customers need

only some specific pitches and mechanical linking (by gears),

putting an ¡§screen¡¨ sometimes will attract operators curiosity to

¡§try¡¨ the monitor and damages caused by these ¡¨innocent¡¨ movement.

The lost of you is not replacing a new monitor only but you loose

the precious time for production. First of all, most of time , customers need

only some specific pitches and mechanical linking (by gears),

putting an ¡§screen¡¨ sometimes will attract operators curiosity to

¡§try¡¨ the monitor and damages caused by these ¡¨innocent¡¨ movement.

The lost of you is not replacing a new monitor only but you loose

the precious time for production.

Secondarily , The demand of ¡§high

accuracy¡¨ products is required nowadays, this is more critical for

making communication cable , such as pairing telephone cable ,CAT5A,

CAT6, CAT7 LAN cable ,or SATA cable. With the bandwidth requirement

is getting higher and higher. Under such circumstances ,

gear-linking bunching machine has much

better performance than so called ¡§synchronization¡¨ multi-motor

system. The weakness of multi-motor system can be seen especially

during the speed ramping up / down period of time or emergency stop

activated , the consistency of the products is highly questioned .

Finally , for some developing

countries , such as South-Eastern Asia , Middle Asia , Africa, South

America¡Ketc , maintenances is more difficult , this situation is

more obviously since they are short of parts and technology,

Mechanical parts for them is much easier for them rather than

electronic devices because

electronics

devices are difficult to find substitutes which delay

production. Mechanical parts are much easier to find replacements or

made from local workshop

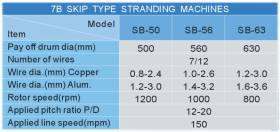

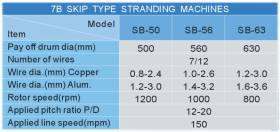

Another stranding machine with

high efficiency is so

called SKIP(BOW) type stranding machine.

This machine

is designed especially for 3-4 core cables stranded together. Another stranding machine with

high efficiency is so

called SKIP(BOW) type stranding machine.

This machine

is designed especially for 3-4 core cables stranded together.

This model is a

substitute of traditional and low speed planetary laying up machine. This

efficiency this machine performs

can up to 10 times of planetary laying up machine in some

cases with ¡§BACK TWIST¡¨ merit.

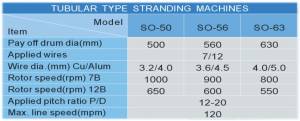

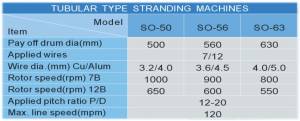

Another stranding with

¡§BACK TWIST¡¨ functionality is the most famous stranding machine-

Tubular stranding machine.

Just like it name, the center of this machine is like

a tube inside which the payoff bobbins being placed. This machine is

especially for high quality products without scarifying production speed. It is most

suitable for 1+6 , 1+6+12 copper wire stranded the bunching / double

twister machine can not

perform well. Another stranding with

¡§BACK TWIST¡¨ functionality is the most famous stranding machine-

Tubular stranding machine.

Just like it name, the center of this machine is like

a tube inside which the payoff bobbins being placed. This machine is

especially for high quality products without scarifying production speed. It is most

suitable for 1+6 , 1+6+12 copper wire stranded the bunching / double

twister machine can not

perform well.

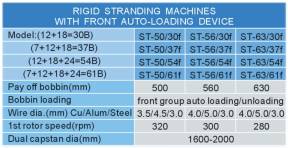

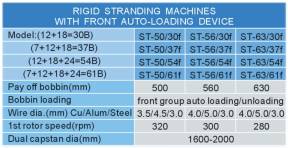

Those machines

showing above are like light-weight boxers comparing to the machines

introduced here. The first one is the most demanded machine

: Rigid stranding machine. Those machines

showing above are like light-weight boxers comparing to the machines

introduced here. The first one is the most demanded machine

: Rigid stranding machine.

Rigid stranding machine , to

power cable makers, are a necessities since this machine is for

multi-layer wire stranding . This

full line of this machine can

strand 1+6 , 1+6+12, 1+6+12+18, and 1+6+12+18+24 wires.stranded from

1 to 4 layers with alternative stranding

directions, except the applications showing above, this machine can

achieve more layer products by just going through this machine twice,

such as 91 wires with 5-layers stranded wires. Rigid stranding machine , to

power cable makers, are a necessities since this machine is for

multi-layer wire stranding . This

full line of this machine can

strand 1+6 , 1+6+12, 1+6+12+18, and 1+6+12+18+24 wires.stranded from

1 to 4 layers with alternative stranding

directions, except the applications showing above, this machine can

achieve more layer products by just going through this machine twice,

such as 91 wires with 5-layers stranded wires.

Since this machine is a

huge amount of investment to cable factory, different applications

should be performed on this machine as well

, such as Armoring , Sector cable with pre-twist pitch, and compact

the core wires before stranding. We

have models with Side loading ¡V unloading , manual / auto loading

modes as an option for customer. Since this machine is a

huge amount of investment to cable factory, different applications

should be performed on this machine as well

, such as Armoring , Sector cable with pre-twist pitch, and compact

the core wires before stranding. We

have models with Side loading ¡V unloading , manual / auto loading

modes as an option for customer.

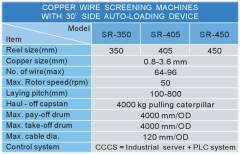

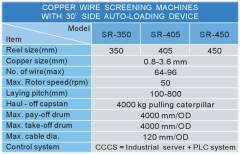

Under some special

circumstances, such as

armoring / screening application which rigid stranding machine can not

achieve, Screening machine

become one of the choices for customer.

Normally this machine is

working with couple taping machine warping

the armored immediately after it being armored. This machine showing

here with our pride are the biggest screening machine we make

in Asia and we are the only one who are capable of making this machine in Asia

cable machinery manufacturing. This machine showing

here is 96 bobbin in one stranding cage ,

bobbin size can up to 450mm. This machine is also

equipped with a side-loading / unloading device for automation. Normally this machine is

working with couple taping machine warping

the armored immediately after it being armored. This machine showing

here with our pride are the biggest screening machine we make

in Asia and we are the only one who are capable of making this machine in Asia

cable machinery manufacturing. This machine showing

here is 96 bobbin in one stranding cage ,

bobbin size can up to 450mm. This machine is also

equipped with a side-loading / unloading device for automation.

If special cable with ¡§BACK

TWIST¡¨ is necessary, Laying up machine

may be their best choices. This is especially can be seen

on 1+3 ,1+4, or even 1+1+3 Sector-type cables which is the stand

specification in some countries. When conductor being preformed by

the rigid stranding machine, after

extrusion process, Planetary laying up machine is the

one and the best one for Laying-up these ¡§sector¡¨ shape cable into a

round one. By making this cable , our laying-up machine are

equipped with position / angle sensor to detect the laying-up angle

of each one of the cables to make sure the perfect ¡§round shape¡¨

cable being made. These sensors can adjust the cable feeding angle

automatically. This is a great beneficiate for cable production and

we are one of the few who know how to make it perfectly with

efficiency. If special cable with ¡§BACK

TWIST¡¨ is necessary, Laying up machine

may be their best choices. This is especially can be seen

on 1+3 ,1+4, or even 1+1+3 Sector-type cables which is the stand

specification in some countries. When conductor being preformed by

the rigid stranding machine, after

extrusion process, Planetary laying up machine is the

one and the best one for Laying-up these ¡§sector¡¨ shape cable into a

round one. By making this cable , our laying-up machine are

equipped with position / angle sensor to detect the laying-up angle

of each one of the cables to make sure the perfect ¡§round shape¡¨

cable being made. These sensors can adjust the cable feeding angle

automatically. This is a great beneficiate for cable production and

we are one of the few who know how to make it perfectly with

efficiency.

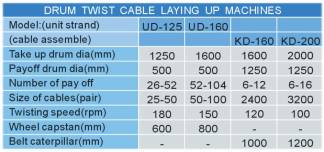

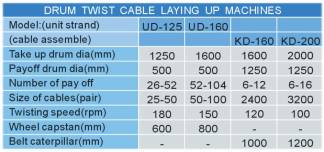

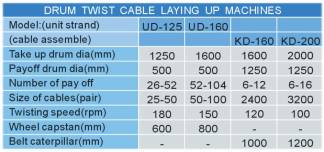

The final one is the

most heavy-duty one ¡V Drum twisting machine

line. With co-accessories This machine is

designed for

multi-purpose applications . If it is equipped with

sub-payoff stands then it can be cable laying up machine . If it

is equipped with steel wire basket payoff stands , it can act like a

armoring machine. It can

also laying up a bunch of telephone wires ( split into some sub

bunches) into one major core. The disadvantage of this machine is the

huge scale which need a lot of space and investment . Since it is a

giant machine,

production speed is also one of its flaw. Even though the

disadvantages showing above, this model is still one of the most

important equipments when we evaluate the capability of production

because this machine offer

non-back twist functionality which cannot achieve. The final one is the

most heavy-duty one ¡V Drum twisting machine

line. With co-accessories This machine is

designed for

multi-purpose applications . If it is equipped with

sub-payoff stands then it can be cable laying up machine . If it

is equipped with steel wire basket payoff stands , it can act like a

armoring machine. It can

also laying up a bunch of telephone wires ( split into some sub

bunches) into one major core. The disadvantage of this machine is the

huge scale which need a lot of space and investment . Since it is a

giant machine,

production speed is also one of its flaw. Even though the

disadvantages showing above, this model is still one of the most

important equipments when we evaluate the capability of production

because this machine offer

non-back twist functionality which cannot achieve.

|

Pan-Pioneer

promote our variety of stranding

devices for different applications. During this slight-profit years,

We devote a lot of efforts on design and manufacturering for

cost-down without sacrificing anything. For each stranding machine models

we have different options for different applications. We also offer

custom-design service for special need from Buyers. This is based on

our knowledge to cable manufacturing and well-experienced design

team group who can satisfy customers with design of

creativity.

Pan-Pioneer

promote our variety of stranding

devices for different applications. During this slight-profit years,

We devote a lot of efforts on design and manufacturering for

cost-down without sacrificing anything. For each stranding machine models

we have different options for different applications. We also offer

custom-design service for special need from Buyers. This is based on

our knowledge to cable manufacturing and well-experienced design

team group who can satisfy customers with design of

creativity.