|

Pan-Pioneer

promote our variety of taping machine for our customer with proud.

Starting for metal , non-metal and mica tape Pan-Pioneer design

differences types of taping machine for different material of tape .

Basically there are

two categories of taping machine ,ie ,concentric and eccentric type

of taping machine. All these eccentric / concentric Taping machine are designed with a user-friendly oriented operation control panel,

such as automatic tension adjustment, S/Z taping direction selectable,

overlapping ratio and layers of tapes , Operator just key in the basic

information , such as tape width , tape thickness, overlapping ratio ,

the control system calculate

the taping ¡§engage angle¡¨ automatically., and

TFT screen monitor for information display The overlapping

range of taping machine are adjustable  directly on the control panel

by adjusting the ratio of taping head speed and line speed. The taping

angle will be adjusted automatically. Besides, we offer wire-broken,

tape-broken and tape run-out sensor which really help the operator no

need to standby besides

this taping machine during operating.

directly on the control panel

by adjusting the ratio of taping head speed and line speed. The taping

angle will be adjusted automatically. Besides, we offer wire-broken,

tape-broken and tape run-out sensor which really help the operator no

need to standby besides

this taping machine during operating.

Except

the merits showing above, all the taping machine are equipped with a high

sensitive tension control system. Tension control is very important

which affect the quality of the taped cable and wire , especially for

Mica taped one. Pan-Pioneer utilize a hysteresist tension brake

which

is controlled by DC voltage. This device is highly accurate with

contact-less design therefore it will never be worn out. The

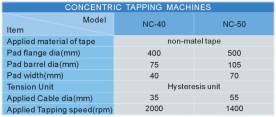

first type of taping machine is so-called

con-centric taping machine.

The cable / wire go through the center hole of the tape .

The

advantage of the design is to operate the

machine at high speed and

get a better accurate taping quality than other model. Pan-Pioneer

design this taping head can be operated independently therefore user

can choose how many layer of tape on the cable. In other words, user

can cascade as many taping head as they need and this taping line is

¡§expendable¡¨ for the future. The

advantage of the design is to operate the

machine at high speed and

get a better accurate taping quality than other model. Pan-Pioneer

design this taping head can be operated independently therefore user

can choose how many layer of tape on the cable. In other words, user

can cascade as many taping head as they need and this taping line is

¡§expendable¡¨ for the future.

Another

type of taping machine is eccentric type taping

machine, Unlike the

cable passing through the center of the tape pad center, taping head

is circling around the cable and multi-tape pads can be placed. In

other words, the performance of a eccentric taping head can be equal

to several concentric Another

type of taping machine is eccentric type taping

machine, Unlike the

cable passing through the center of the tape pad center, taping head

is circling around the cable and multi-tape pads can be placed. In

other words, the performance of a eccentric taping head can be equal

to several concentric taping heads. The disadvantage of this design is

due to the less accuracy of overlapping achievement or the difficulty

of tension control due to the long path of the tape route, these

conditions sometimes are not acceptable especially for some

applications, such as Mica tape , Mylar tape or even paper tape.

Eccentric taping machine are most suitable for metal tape , such as

steel tape, copper tape, etc since it is capable of heavy-load

circumstances. Since it is design for heavy-duty condition, the

twisting speed of this head is less than the concentric type taping

head. taping heads. The disadvantage of this design is

due to the less accuracy of overlapping achievement or the difficulty

of tension control due to the long path of the tape route, these

conditions sometimes are not acceptable especially for some

applications, such as Mica tape , Mylar tape or even paper tape.

Eccentric taping machine are most suitable for metal tape , such as

steel tape, copper tape, etc since it is capable of heavy-load

circumstances. Since it is design for heavy-duty condition, the

twisting speed of this head is less than the concentric type taping

head.

The

last one is what we call Mica tape taping machine, This

taping machine is

design, especially suitable , for cable need to be taped by Mica

material. As we know the tension of the mica tape is very fragile and

broken easily .The most critical for mica tape taping is due to the

products is for fire resistant purpose, the coverage of mica quality

will affect directly for fire resistance test.

Normally 2 mica taping

head with overlapping ratio 50% is the standard requirement. This will

equal to 4 layers on the shielded cable.

The most special part

of this taping machine

we use on this taping machine is

its dynamic tension adjustment device which will eliminate the

uncertain factors which will affect the accuracy of the tension

control. The

last one is what we call Mica tape taping machine, This

taping machine is

design, especially suitable , for cable need to be taped by Mica

material. As we know the tension of the mica tape is very fragile and

broken easily .The most critical for mica tape taping is due to the

products is for fire resistant purpose, the coverage of mica quality

will affect directly for fire resistance test.

Normally 2 mica taping

head with overlapping ratio 50% is the standard requirement. This will

equal to 4 layers on the shielded cable.

The most special part

of this taping machine

we use on this taping machine is

its dynamic tension adjustment device which will eliminate the

uncertain factors which will affect the accuracy of the tension

control.

Another

special design for this taping machine is the ¡§spooler¡¨ tape application,

You will under stand how wonderful of this design without my

introduction when you see the attached photo. No need for

operator

replace new tape for one shift.

¡@

|