|

|

|

|

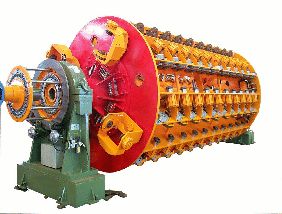

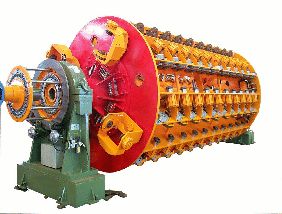

Rigid Stranding machine is one of the most popular type of stranding machine in cable/wire business. This is because of its variety of application. |

|

Rigid Stranding Machine

¡@

|

|

|

|

Rigid Stranding machine is one of the most popular type of stranding machine in cable/wire business. This is because of its variety of application. |

|

The

rigid stranding machine can apply to variety of wire production purpose.

There are 4 kinds of rigid stranding machines however the

design concepts are identical. For example , you can have one segment with 6

cages which is just for 7 wires stranding purpose. If you are looking for 13

wires stranding , you can have one cage with 12 cages . if you have two lineup

segments (one is 6 cages type and the other is 12 cagess type) , then you

can have 7/13/19 wires stranding application . Based on the same concept , the

more segments lineup , the more combination you can get. However , by following

the rules of the cable specifications , the most common layout of the rigid

stranding machine is with 4 segments : 6 cages + 12 cages + 18 cages + 24

cages. you can see the following table for more details.

|

Combination Table |

|

| A

: 6B CAGES B : 12B CAGES C : 18B CAGES D : 24B CAGES |

|

| 7wires | A |

| 19wires | A+B |

| 37wires | A+B+C |

| 61wires | A+B+C+D |

Of course , for the budget buyers , it is not necessary to purchase the whole lineup if they want to make 61wire stranding . There are several alternative way to achieve this goal. For example, if you have a 7 reel tubular stranding machine already , then you can save the money without buying the 6 reel cage. If you are still want to save more ( this is also what we suggest to our customers) , you can save the money from 24 reel cage instead of going through the machine twice when you produce 61wire stranding. This is how we do for 61wire stranding .

The other approach is to use 48 , 84 ,or even 96 bobbins in one cage for special purpose, such armoring , steel wiring lane-up , or high voltage copper wire stranding. The size of the bobbins , or course, are smaller than the multi-cage strander. Normally , it is smaller than 400mm DIN size for safety purpose.

¡@